Abstract

GB 8939-2019 specifies the test method for the absorption speed of

sanitary napkins. In actual work, it is found that different factors will affect the test results. The influence of storage time of standard synthetic test solutions and processing time of

sanitary napkins under standard atmospheric conditions on the measurement results was studied. The results show that the standard synthetic test solution after preparation is properly stored for the first 2 months, and the test samples which are processed for 4 hours or longer under standard atmospheric conditions have the highest test accuracy.

The speed of blood absorption reflects the comfort and safety of the

sanitary napkin during use. Standard GB/T 8939-2018

Sanitary Napkins or Pads added absorption speed index~3 evaluates absorption speed by processing standard synthetic test solutions (pig blood substitute) for 4 hours under standard atmospheric conditions specified by the GB/T 10739. It is confirmed that the standard synthetic test solution can be stored for a long time after preparation in the laboratory, but the specific time has not been studied. This article studies the influence of the storage time of the synthetic test solution and the treatment time of sanitary napkins under standard atmospheric conditions on the absorption speed, so as to obtain the best test conditions.

1

Test methods

1.1

Instruments and reagents

Instruments: the absorption speed tester (ZZ-XSY-1), cup No. 4 (NDJ-5), density bottle and automatic surface tension meter (BZY Series)

Samples: Sanitary napkins

Reagents: Sodium chloride, anhydrous sodium carbonate, sodium carboxymethyl cellulose, sodium benzoate, glycerol, standard coal agents, all reagents are analytical pure.

1.2

Experimental steps

According to GB/T 8939-2018

Sanitary Napkins or Pads standard regulations, prepare the standard synthetic test solution and put it aside for 24 hours, and then verify its density, viscosity and surface tension. Test the

sanitary napkin samples processed for different time under standard atmospheric conditions. Store them in a cool place away from sunlight for several months. After verifying its indicators, test the absorption speed of sanitary napkins. Repeatedly test each set of data for seven times, and use spss software to process data results and analysis.

2.1

The influence of storage time of standard synthetic test solutions on absorption speed

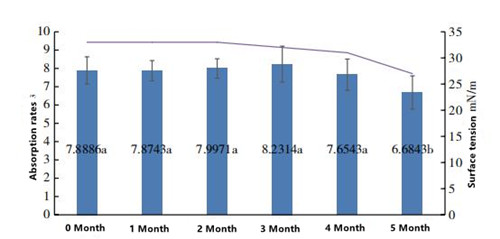

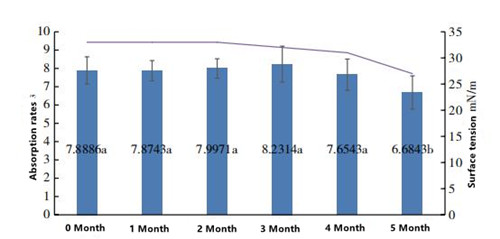

Prepare a standard synthetic test solution and put it aside for 24 hours. It’s density is 1.05 ± 0.05 g/cm3, viscosity 11.9 ± 0.7s and surface tension (36 ± 4) mN/m. Store it in a cool place away from sunlight for several months and verify its related indicators. The results showed that the density and viscosity did not change, only the surface tension changed. See the Figure 1. Use this standard synthetic test solution to test the absorption speed of sanitary napkins in the same batch. The results showed that there was no significant difference in the absorption rate of the standard synthetic test solution in the first 4 months, but the standard deviation was only low in January and February. The surface tension value remained unchanged for the first 2 months, but at the third month it started to decrease and fall below the standard requirement (27mN/m) in the fifth month.

Figure 1 The effect of storage time of synthetic test solutions on absorption rates

2.2

The influence of sample processing time on absorption rates under standard atmospheric conditions

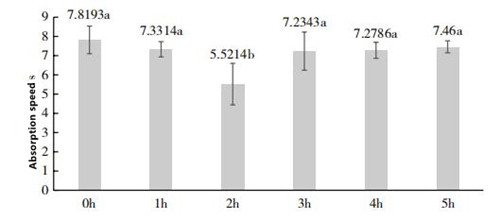

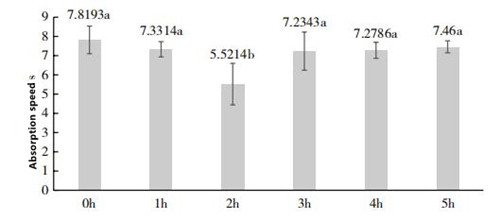

After the

sanitary napkin sample is processed under standard atmospheric conditions [(23±1 ℃; (50±2)%], a standard synthetic test solution with 1.035g/cm3, 12.5s and 33mN/m is prepared and set aside for 24 hours to test the absorption rate. The relationship between the treatment time and the absorption rate under standard atmospheric conditions is shown in the Figure 2. The results show that the sample processing time in the standard atmosphere has no significant influence on the absorption rate except for 2 hours, but as the processing time increases, the test value tends to stabilize. The standard deviation is the smallest when the processed time is 5 hours.

Figure 2 The influence of different treatment time on the absorption rate under standard atmospheric conditions